Technical Textiles for a Sustainable Future

Challenge Outdoor is committed to meeting the rugged demands of adventure-seekers while protecting our planet. We use renewable energy and recycled components to engineer high-performance textiles that are durable, lightweight, and waterproof.

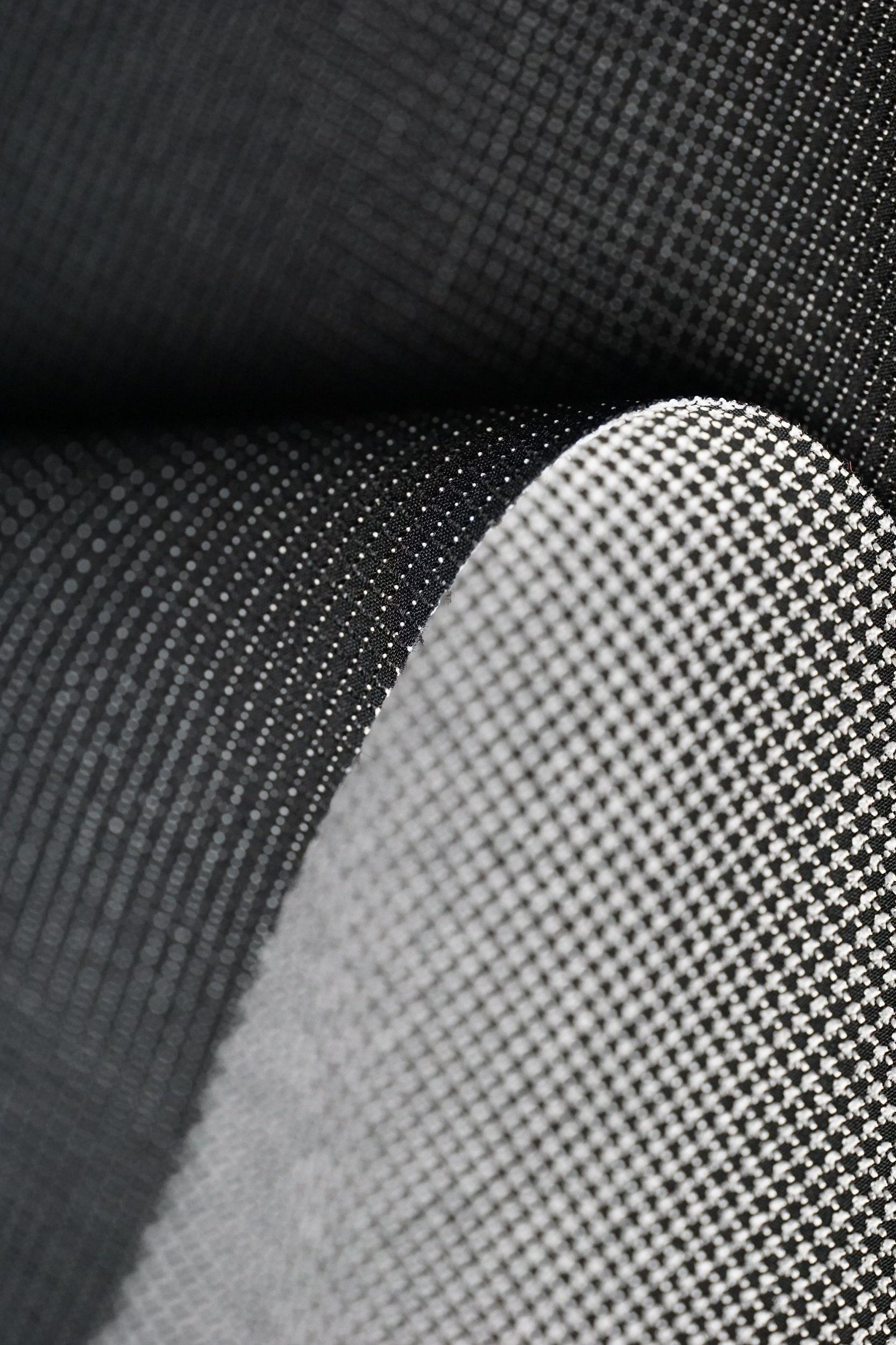

Sustainable Composite Textiles

-

Recycled Fabric

ECOPAK™ is the world’s only composite fabric made with 100% recycled fiber and film. Constructed with REPREVE® rPET fiber, our fabric lasts longer, absorbs 80% less moisture, and has better UV resistance and color retention than traditional laminated nylon.

-

Non-Toxic Adhesive

These materials are laminated into composite fabrics, using our proprietary adhesive, which does not contain toxic solvents or VOC’s (Volatile Organic Compounds). Others laminate with solvent-based adhesives necessitating energy-intensive drying ovens. They may claim to be ‘carbon neutral’ by buying carbon-offsets after polluting; Challenge has taken the progressive step of eliminating harmful chemicals from the start!

-

Recycled Film

The proprietary Challenge RUV™ film backing is 100% recycled and 97% UV resistant. Challenge RUV™ lasts 5 times longer in the sun than conventional film used in other fabrics - a big breakthrough in extending performance.